Thrust ball Bearings

Description

Needle roller thrust bearings are fitted with a form-stable cage to consistently retain and control a large number of needle rollers. Very small diameter deviance of the rollers within one assembly allows these bearings to house heavy axial loads and shock loads. The ends of these rollers are released somewhat to modify the line contact between rollers and the raceways. This invariably avoids stress peaks at roller ends to provide durability. They provide an enhanced degree of stiffness in limited axial space. Applications where faces of adjacent machine components are built to serve as raceways, this needle roller thrust bearings take up no more space as compared to traditional a thrust washer.

Application

- Snares

- Mash refiners requisitions

- Mechanical provisions

- Oil well swivels requisitions

- Extruder and puncturing plants requisitions

- Utilized within tubing rotators provisions

- Utilizing within moving plants requisitions

- Vertical crushing machines

- Vertical exhausting factories

- Wavering provisions

Cylindrical Roller Thrust bearings

Description

Cylindrical Roller Thrust Bearings are the ones specifically designed to house heavy axial and shock loads. However; subjecting them to radial load is not allowed. With this Cylindrical roller thrust bearings the ends of the rollers are relieved to some extent to alter the line of contact between raceways and rollers. This is done in order to avoid stress peaks at roller ends to prolong bearing service life. They can carry heavy axial loads. Furthermore, they are stiff and oblivious to shock loads and they require little space. They are mainly used in applications where load carrying capacity of thrust ball bearing is inadequate.

Application

- Declaration devices

- Electricity generators

- Gas turbines

- Internal combustion engines

- Industrial machine

- Machine tool spindles

- Used in middle-sized and large-sized motors applications

- Unloading and lifting machines

- Transmissions

- Gearboxes applications

Needle Roller Thrust bearings

Description

Needle Roller Thrust Bearings are fitted with a form-stable cage to consistently retain and control a large number of needle rollers. Very small diameter deviance of the rollers within one assembly allows these bearings to house heavy axial loads and shock loads. The ends of these rollers are released somewhat to modify the line contact between rollers and the raceways. This invariably avoids stress peaks at roller ends to provide durability. They provide an enhanced degree of stiffness in limited axial space. Applications where faces of adjacent machine components are built to serve as raceways, this needle roller thrust bearings take up no more space as compared to traditional a thrust washer.

Application

- Gear pumps

- Hydraulic pumps

- Mud pumps

- Material handling instrumentation

- Oil field pumping jacks

- Paper punch presses

- Sheave Blocks

- Tele handlers

- Marine crankshafts and connecting rods

- Pipe handling tables in manufactory instrumentation

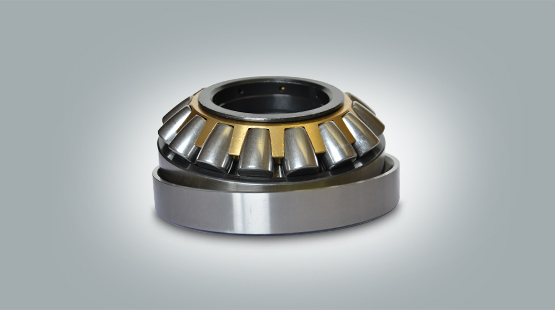

Spherical Roller Thrust Bearings

Description

Spherical Roller Thrust Bearings are the ones with specially designed raceways that can house large number of asymmetrical rollers. These rollers have finest conformity with washer raceways to enhance load distribution across the roller length. Hence, they are able to house relatively high speeds, heavy axial loads in one direction and heavy radial loads. These Bearings are intended to work in environments where grim misalignments exist, either from mounting or shaft diversion. Best feature about these bearings is that they are self-aligning and can house misalignment of the shaft relative to the housing caused due to shaft deflection.

Application

- Hydroelectric generators

- Vertical motors

- Propeller

- Axle of vessels

- Tower cranes

- Squeezing pressed

- Metal mill work/back-up rolls

- Pre-heater fans

- Pumps

- Implemented in screw conveyors